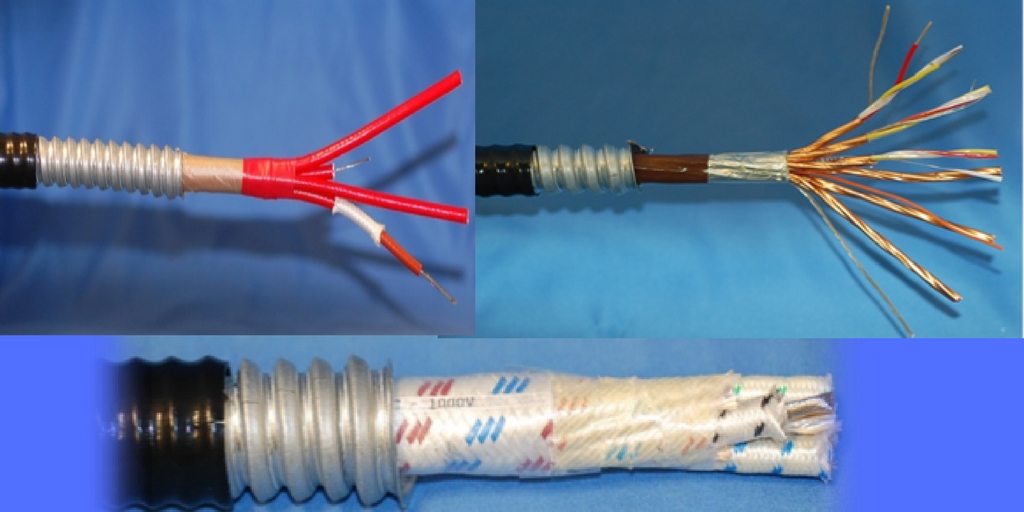

Historically, the single conductor cables, whether they be thermocouple duplex wire or single conductor HEI wire were purchased separately. Then these single wires were then fed through a conduit. This process is cumbersome, expensive, and doesn’t manage the cable well regarding cable management and lay inside the conduit. Often, glass braided cables or thin-skinned Teflon® insulated cables could be damaged during this process on a burr or sharp edge, etc.

Thermal Wire has solved this process by supplying the cable assembled in the armor and sealed from the elements. Furthermore, this system provides a factory assembled, armored and jacketed cable. HEI composite hybrid is available and is armored with continuously welded and corrugated stainless steel, galvanized steel interlock or aluminum interlocked armor. Three jacketing types are available 200°C, 250°C, or 300°C. Jacketing is optional. The jacket seals and encapsulates the armor and provides a jacket that is resistant to all known chemicals except solid bases. Sound cable design considerations, and the use of high-quality state of the art insulating materials, coupled with solid American Craftsmanship substantially positively influence the cable’s performance.

The electrical wire delivering the charge to this system and the thermocouple wire play a vital role and work in harmony with each other to ensure circuit integrity. As with all systems, the electrical wire needs to be carefully considered. Many design notes include Voltage rating, oil and moisture resistance, Standards Agency Requirements, armor requirements, routing considerations, UV resistance, etc. lengths of cable, finished OD, weight, etc.

Take a look at our presentation to see the various cable solutions

[slideshare id=71164286&doc=armoredheicables-170118233241]